Sensor Installation Examples

Below are some examples of machines that smart shop floor sensors have been installed on.

Rottler Machines

Sf8A

The sensor is installed on the top casing above the internal motor. The allows for effective vibration capture and good visibilty from a gateway.

F88/F99

Mutiple sensors were isntalled on these models this allow recording of vibration when the machine would move over the object not just drilling.

.png)

Eumach Machines

FBE-2000/FBE-3000

On these machines two sensors were installed to meausre vibration when drilling and moving the item.

Drill Head

Back Casing

Mazak Machines

Quick Turn 250

On this lathe and similar one the sensors was tested on multiple area. It was first placed on the motor, however on finishing cuts very little vibration would be found.

What was found that whilst cutting the coolant pump is alway on to ensure the metal doesn't heat up. This means that the sensor can be installed on that giving accurate usage.

King Rich machines

AMC1500

The sensor is installed on the top motor. This is also the same spot for similar models.

Sunnen Machines

CV-616

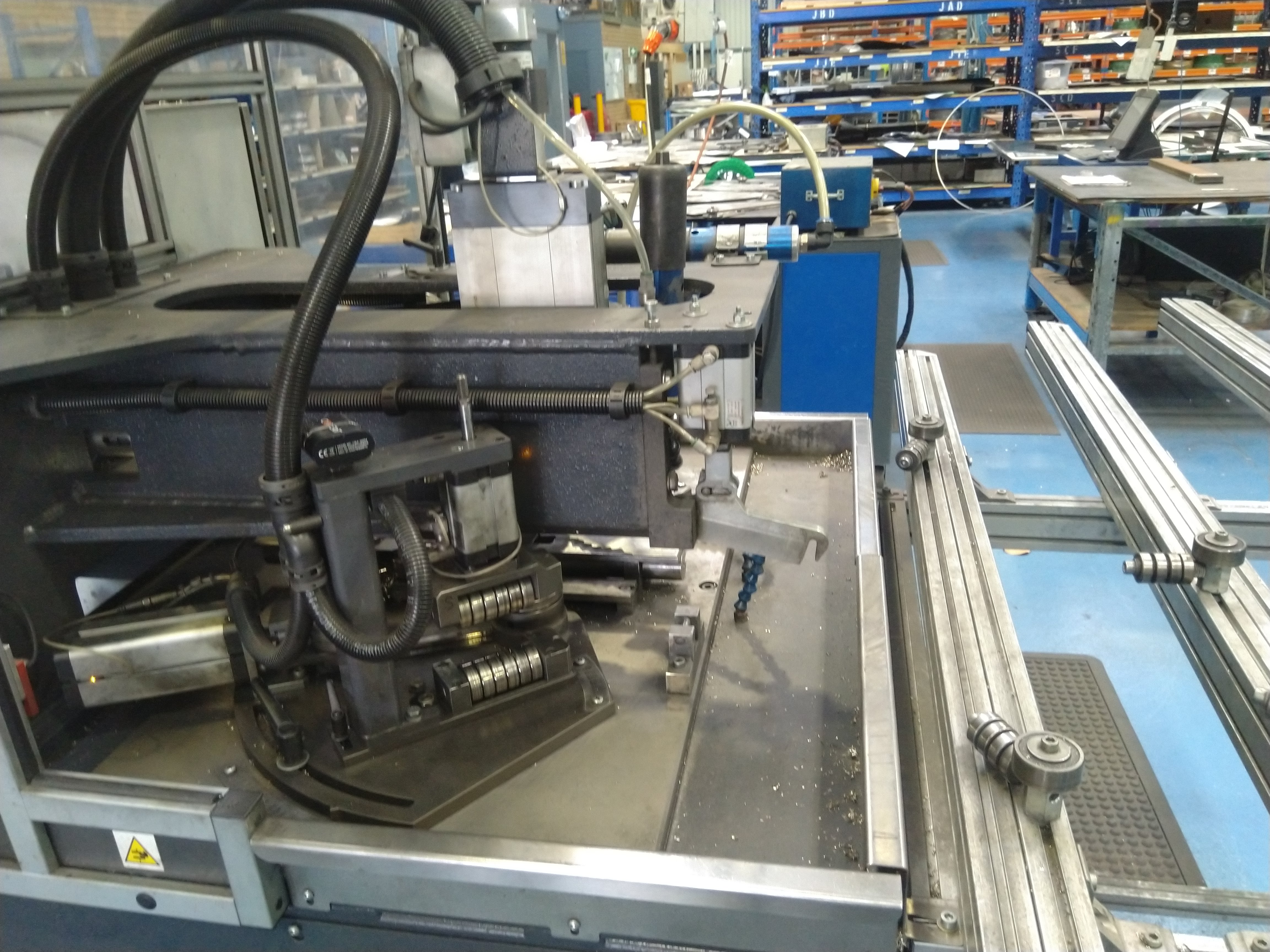

Atom Flashcut Machines

Flex Family

The sensor is installed on the back of the cutting body.

The sensor is installed on the back of the cutting body.

Atom 6 (Older model)

The sensor is placed on the cutting controller inside the case. A gateway is required to be closer to this machine as the casing is metal.

GSKET Machines

MKG03

The sensor is installed on the side arm when the gasket spinning motor is.

The sensor is installed on the side arm when the gasket spinning motor is.

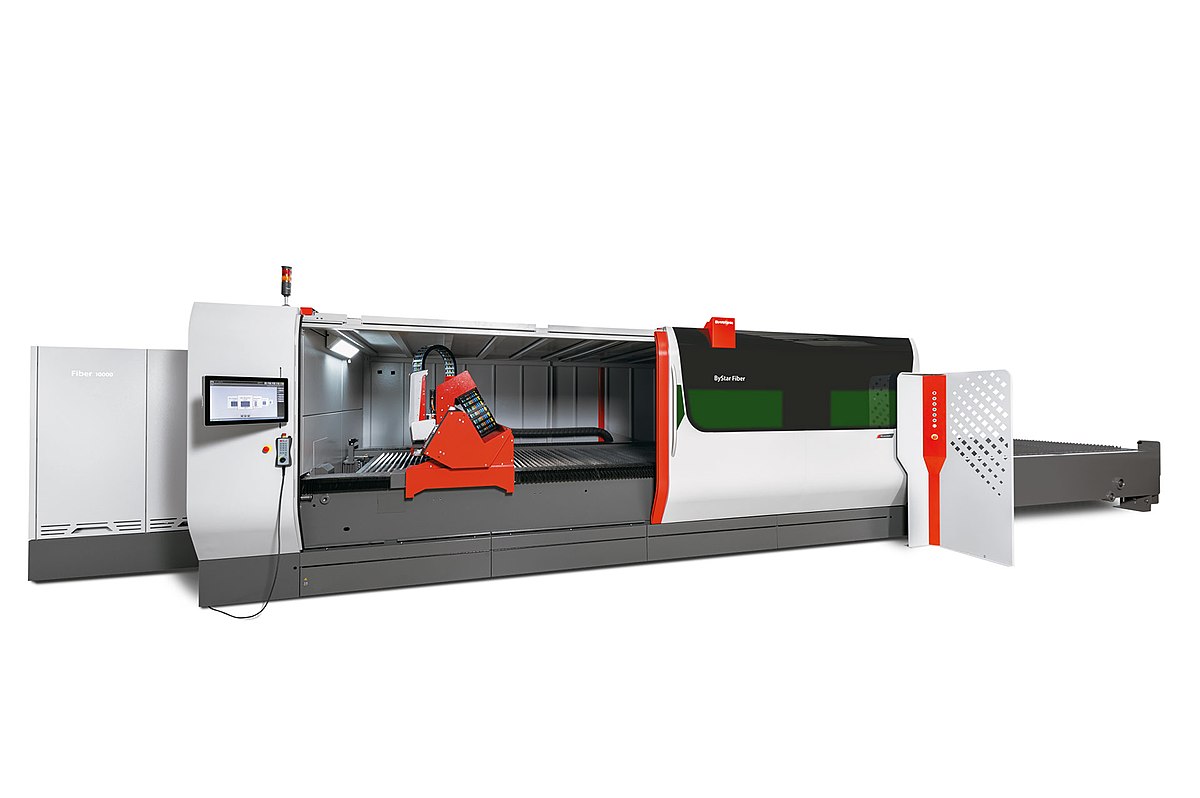

Bystronic Machines

Bystar laser cutter

The sensor was tested on multiple areas of this machine. It was first installed on the moving lazer component but it was found due to its slow movement and efficient electric motor very little vibration would be recorded.

It was then decided to have the sensor installed on the external exhaust unit as it would only be run when the machine is cutting and utilisation could be determined by that.

Deckel Maho Machines

DMC125 2P

The sensor was installed on the back of the casing of the machine.

The sensor was installed on the back of the casing of the machine.

DMU 210P

The sensor is installed on the machine on the top right of this image.

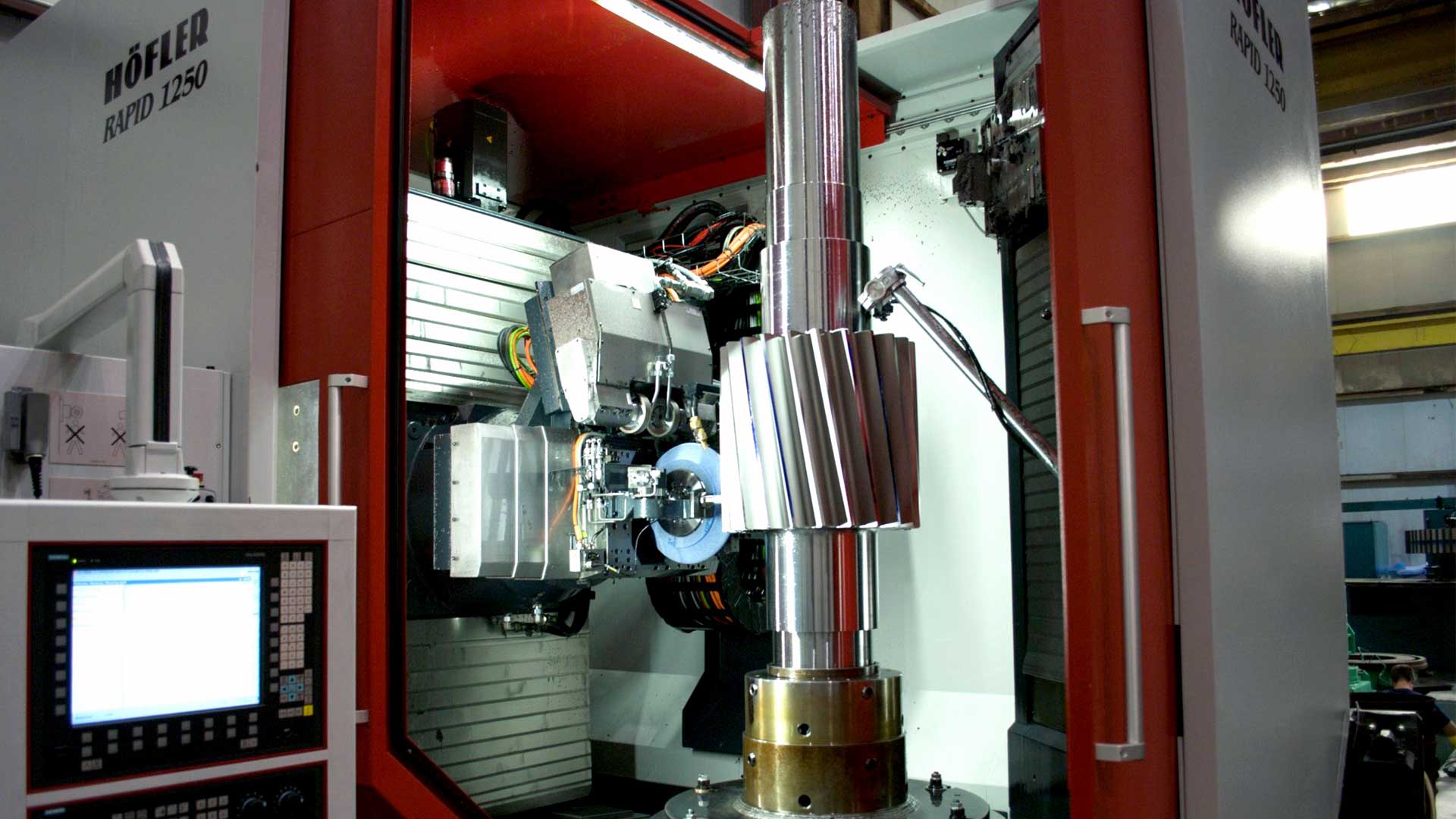

Hofler Machines

Rapid 1250

The sensor is installed on base of the cutting arm inside the unit.

Rapid 2000

The sensor was installed on the outer case just below the Hofler logo.

Gleason-Pfauter Machines

P1600G/P1800G

The sensor was installed just below the 1600G writing on the outer case.